Custom Sizes:1-21 inch (Tailored to Your Needs)

Display mode:IPS

Display color:16.7M

Interface:MIPI

Viewing angle(°):ALL

Brightness(cd/m2):280

Contrast ratio:800

Operation temperature(℃): -20~+70℃

Storage temperature(℃): -30~+80℃

Application:Medical Equipment, New Energy

Anti blackening

the screen content can be clearly seen from any angle.

Anti blackening

the screen content can be clearly seen from any angle.

"3A" processing

Simultaneously equipped with AG+AR+AF processing.

"3A" processing

Simultaneously equipped with AG+AR+AF processing.

Low-power consumption

Extremely low power consumption, the lowest in the industry.

Low-power consumption

Extremely low power consumption, the lowest in the industry.

High sensitivity

Fast scanning and refresh rate, startup below 30MS, excellent accuracy and linearity.

High sensitivity

Fast scanning and refresh rate, startup below 30MS, excellent accuracy and linearity.

Anti-noise

Hardware and firmware can be matched to meet strict EMI/RFI standards.

Anti-noise

Hardware and firmware can be matched to meet strict EMI/RFI standards.

Optical binding

After full bonding, the screen's seismic resistance is increased, reducing the chance of damage.

Optical binding

After full bonding, the screen's seismic resistance is increased, reducing the chance of damage.

01

01

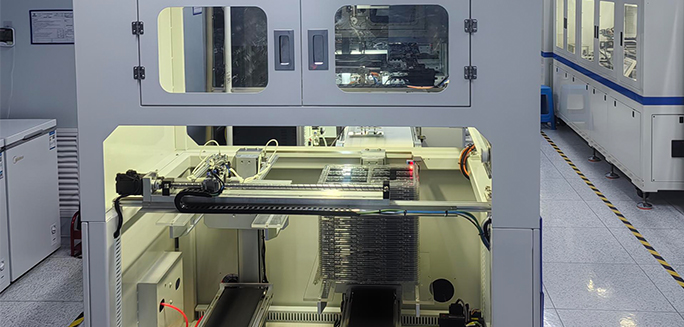

COG/Fully automatic binding process This process is mainly to bind the IC and FPC to the LCD panel until the FOG is formed.

02

02

LCM-Fully automatic film process In this process, FOG and BLD are bonded until LCM is formed.

03

03

Post film process This process is mainly to attach the auxiliary materials to the formed LCM.

04

04

LCM electrical burning test This process is mainly to test the performance of the formed LCM.

05

05

TLCM/Automatic film process This process is mainly to bond LCM and TP until TLCM state.

06

06

Defoaming furnace process This process is mainly to defoam the laminated TLCM.

07

07

FQCinspection area This process is mainly to carry out the final process test of the laminated TLCM finished product.

08

08

Outgoing quality control This process is mainly for TLCM finished product quality inspection before shipment.