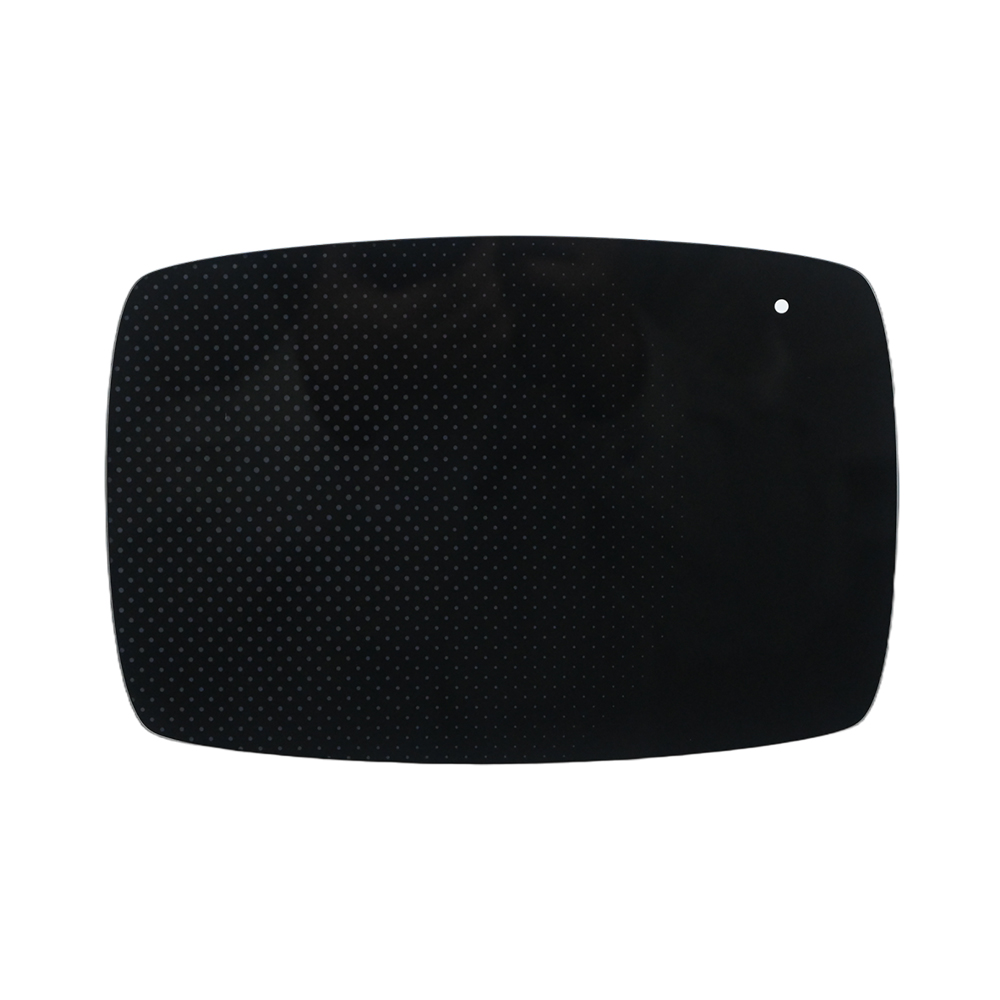

Custom Sizes:1-21 inch (Tailored to Your Needs)

Material:soda-lime/low-ironglass

Optical Data:Transmittance>89%

Strengthening:chemically strengthened (CS>450MPa, DOL>8um)

Impact resistance test: Glass can pass IK08 grade test(e.g. 500g steel ball, 1 meter height drop,glass not broken)

Printing:black, white, gray, UV-resistant ink, out door use for more than 5 years, the ink doesn't change color and fall off.

Bonding:3M 5925,waterproof hight emperature resistant, anti-vibration. It can meet the out door use for up to 5 years.

Certification:ISO9001:2015

Package:Vacuum-packed

Brand: Gelivable

Application:New Energy

Anti blackening

the screen content can be clearly seen from any angle.

Anti blackening

the screen content can be clearly seen from any angle.

"3A" processing

Simultaneously equipped with AG+AR+AF processing.

"3A" processing

Simultaneously equipped with AG+AR+AF processing.

Low-power consumption

Extremely low power consumption, the lowest in the industry.

Low-power consumption

Extremely low power consumption, the lowest in the industry.

High sensitivity

Fast scanning and refresh rate, startup below 30MS, excellent accuracy and linearity.

High sensitivity

Fast scanning and refresh rate, startup below 30MS, excellent accuracy and linearity.

Anti-noise

Hardware and firmware can be matched to meet strict EMI/RFI standards.

Anti-noise

Hardware and firmware can be matched to meet strict EMI/RFI standards.

Optical binding

After full bonding, the screen's seismic resistance is increased, reducing the chance of damage.

Optical binding

After full bonding, the screen's seismic resistance is increased, reducing the chance of damage.

01

01

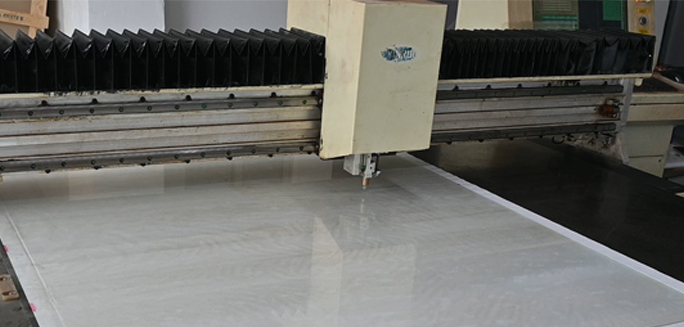

Cutting Glass substrates are cut to target dimensions using diamond tools or lasers, ensuring precision and edge integrity.

02

02

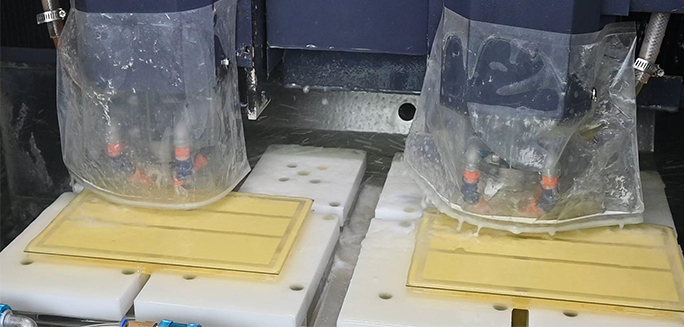

CNC Edging CNC machines grind edges into rounded/beveled shapes for smooth touch and stress reduction.

03

03

Ultrasonic Cleaning High-frequency ultrasonic waves generate cavitation in cleaning solutions to remove oil, dust, and debris from the glass surface, ensuring cleanliness for subsequent processes.

04

04

Chemical Strengthening High-temperature potassium ion exchange forms a compressive layer, boosting strength and impact resistance.

05

05

Physical Strengthening Heat treatment or ion implantation modifies the glass surface structure to increase hardness and wear resistance, suitable for high-strength applications.

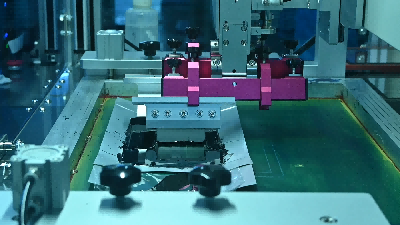

06

06

Printing Screen printing or digital printing is used to apply logos, decorative patterns, or functional coatings on the glass edges or designated areas.

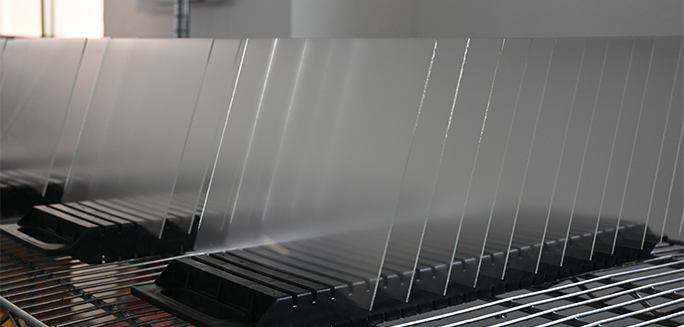

07

07

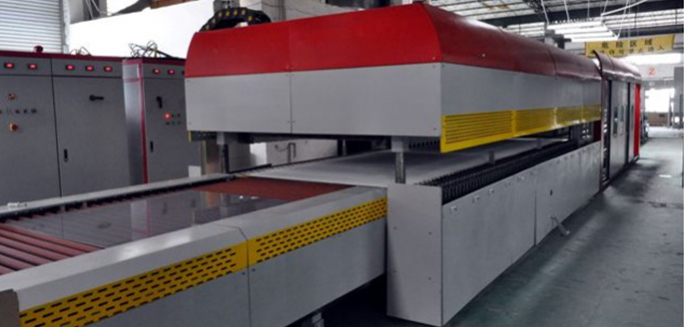

Baking Printed glass is placed in a high-temperature oven to cure inks or coatings, ensuring adhesion, weather resistance, and color stability.

08

08

Surface Treatment (AR/AF/DLC) Coatings (AR/AF/DLC) enhance anti-reflection, fingerprint resistance, or durability.

09

09

Inspection Optical scanners and strength testers are used to inspect dimensions, light transmittance, strength, and surface defects, ensuring compliance with quality standards.

10

10

Packaging Anti-static, shock-proof packaging safeguards products with batch labels for traceability.